mirror of

https://github.com/peter-tanner/Power-and-Machines-notes.git

synced 2024-11-30 09:00:25 +08:00

6.2 KiB

6.2 KiB

Why are the drawings bad?

I draw them with a mouse

Types of power factors (From ENSC2003)

Where \bar{S}=|\bar{S}|\angle\varphi:

\varphi = \arctan\left(\frac{Q}{P}\right) = \theta_v-\theta_i| Lagging | Leading | Unity | |

|---|---|---|---|

| Voltage | Current behind | Current ahead | In phase |

| Load type | Inductive | Capacitive | Resistive |

Q |

Q>0 |

Q<0 |

Q=0 |

\varphi |

\varphi>0° |

\varphi<0° |

\varphi=0° |

| PF [Load] | [0,1) |

[0,1) |

1 |

| PF [Source] | [0,-1) |

[0,-1) |

-1 |

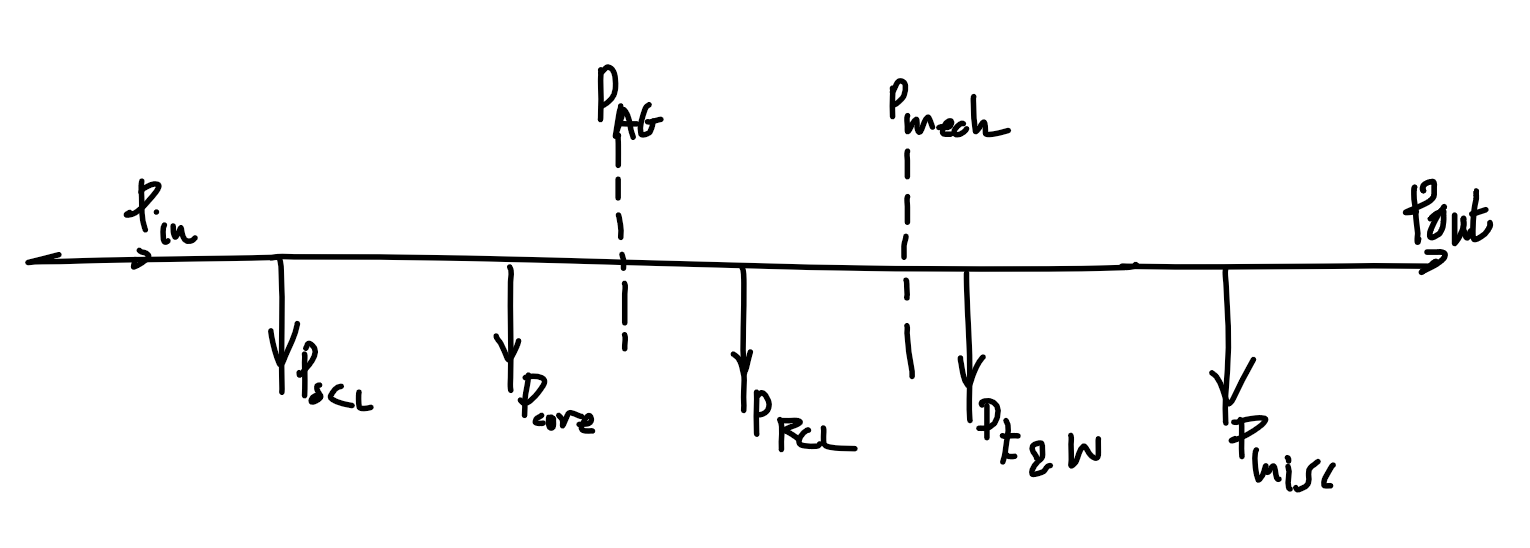

Power types in motor

| Type | Description | Equivalent terms |

|---|---|---|

| Input power | Power into machine. V_T=V_{3\phi}, I_L=I_{3\phi} |

P_\text{in}, \sqrt{3}V_TI_L\cos(\theta) |

| Output power | Mechanical output power of the machine, excludes losses | P_\text{out}, P_\text{load} |

| Converted power | Total electrical power converted to mechanical power, includes useful power and mechanical losses inside machine | P_\text{conv}, P_\text{converted}, P_\text{mech}, P_\text{developed}, \tau_\text{mech}\times\omega_m |

| Airgap power | Power transmitted over airgap. | P_\text{AG}, \tau_\text{mech}\times\omega_s |

| Mechanical loss | Power lost to friction and windage | P_\text{mechanical loss}, P_\text{F\\\&W}, P_\text{friction and windage} |

| Core loss | Power lost in machine magnetic material due to hysteresis loss and eddy currents | P_\text{core} |

| Rotor copper loss | Due to resistance of rotor windings | P_r, P_\text{RCL} |

| Stator copper loss | Due to resistance of stator windings | P_s, P_\text{SCL} |

| Miscellaneous loss | Add 1% to losses to account for other unmeasured losses | P_\text{misc}, P_\text{stray} |

\begin{align}

P_\text{in}&=P_\text{SCL}+P_\text{RCL}+P_\text{core}+P_\text{F\\\&W}+P_\text{misc}+P_\text{out}\\

P_\text{AG}&=P_\text{RCL}+P_\text{F\\\&W}+P_\text{misc}+P_\text{out}\\

P_\text{mech}&=P_\text{F\\\&W}+P_\text{misc}+P_\text{out}

\end{align}

Note - assume loss is 0 if not mentioned!

| Type | Description | Symbols |

|---|---|---|

| Load torque, Shaft torque | Torque experienced by load after all losses | \tau_\text{load}, \tau_\text{shaft} |

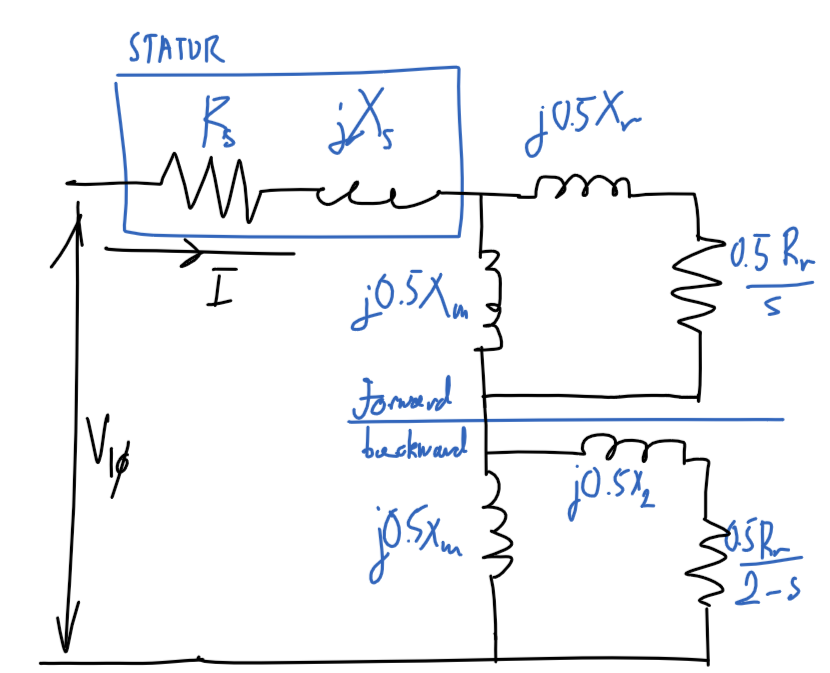

3\phi induction motor

Etc.

-

Slip speed

N_\text{slip}=N_{s\text{ (sync)}}-N_r=sN_{s\text{ (sync)}} -

"1/4 of rated load" != "1/4 times full load"

- Means 1/4 of full load slip as it is in the linear region. Accounts for the minimum load.

-

Rated power stated in machine specification refers to the output power

P_\text{out}, and excludes all losses. -

Speed regulation using machine speed: $$\text{SR}=\frac{N_{r,\text{NL}}-N_{r,\text{FL}}}{N_{r,\text{FL}}}

Diagram

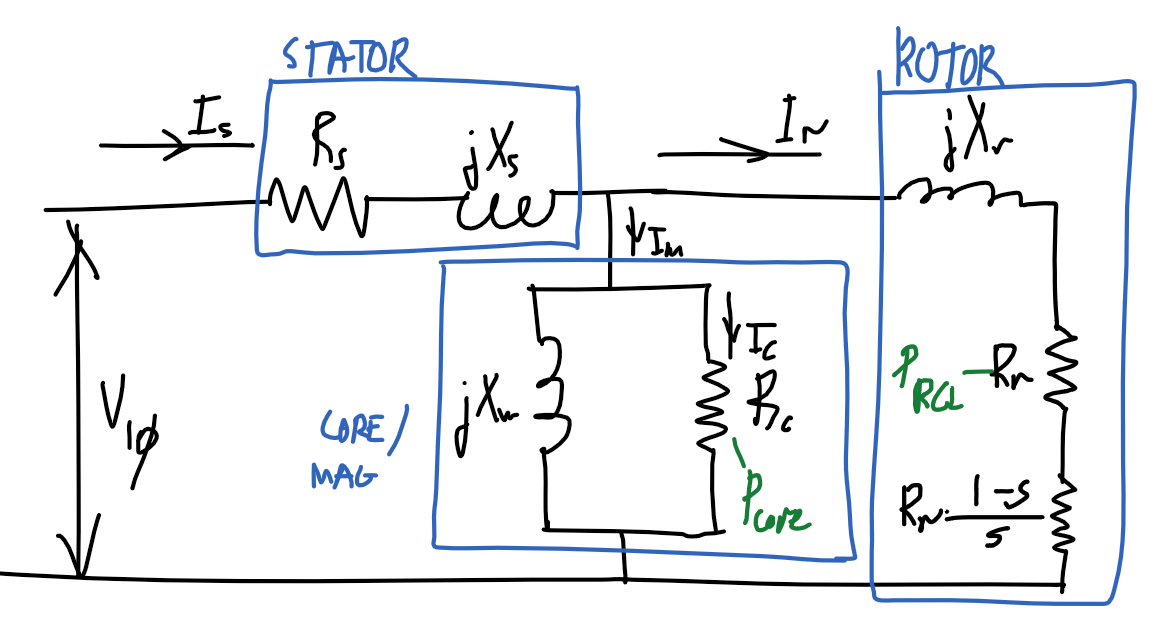

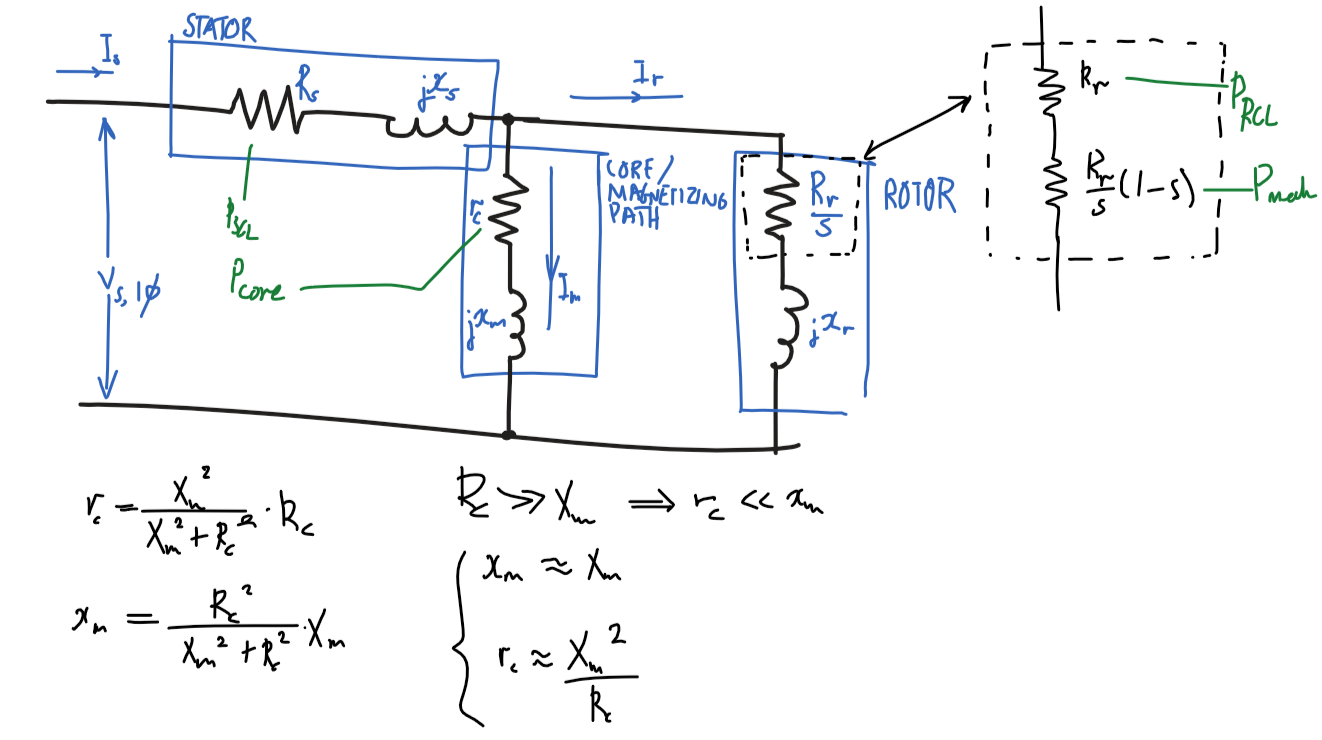

Equivalent model

Assumptions

x_m\approx X_mR_c\ggg X_m\Rightarrow r_c\lll x_mx_m=\frac{{R_c}^2}{{R_c}^2+{X_m}^2}X_m\approx\frac{\cancel{{R_c}^2}}{\cancel{{R_c}^2}}X_m=X_m

r_c\approx {X_m}^2/R_cR_c\ggg X_m\Rightarrow r_c\lll x_mr_c=\frac{{X_m}^2}{{R_c}^2+{X_m}^2}R_c\approx\frac{{X_m}^2}{{R_c}^2}R_c=\frac{{X_m}^2}{R_c}

Diagram

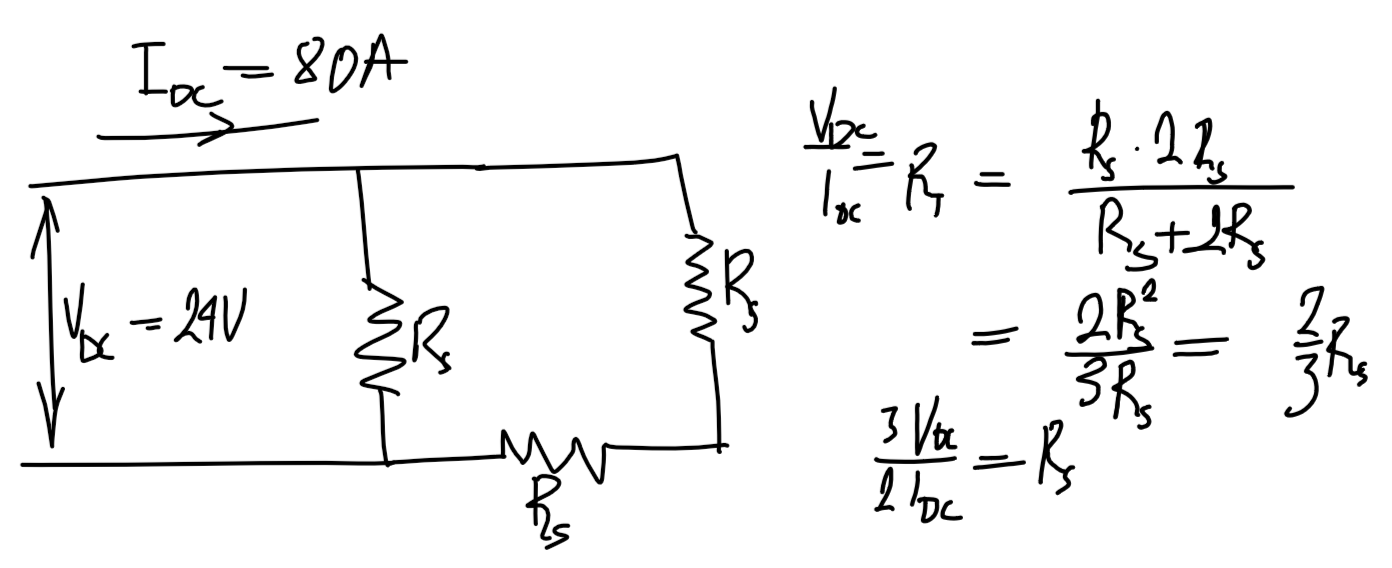

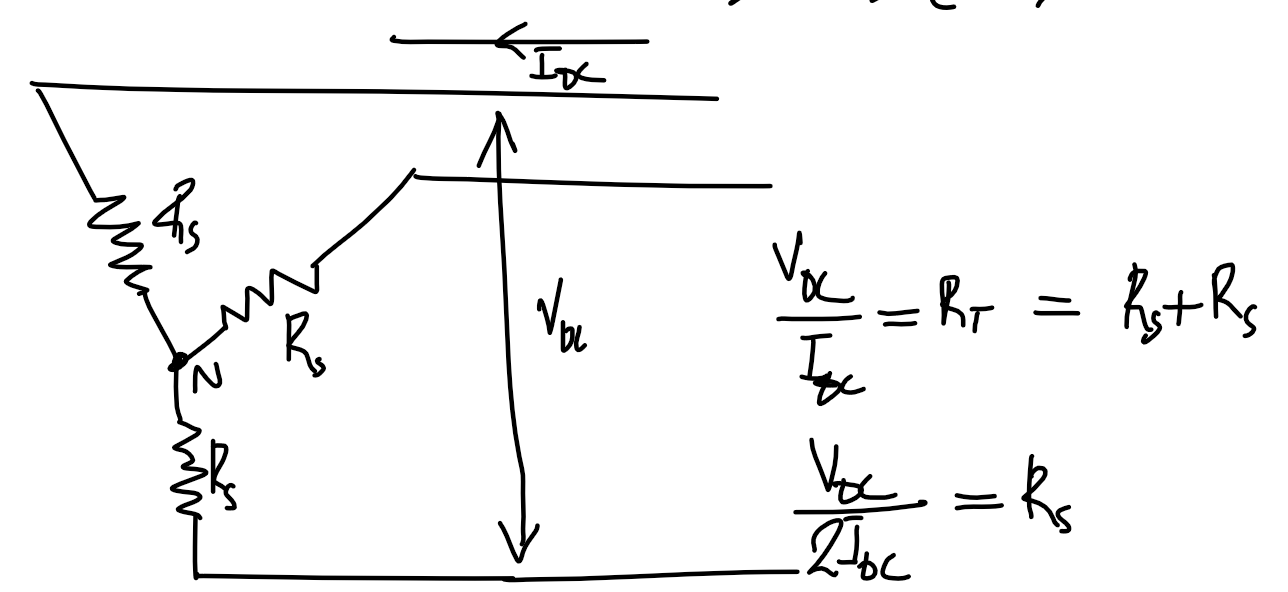

DC test

\Delta machine

R_s=\frac{3}{2}\cdot\frac{V_{\text{DC},3\phi}}{I_{\text{DC},3\phi}}Y machine

R_s=\frac{1}{2}\cdot\frac{V_{\text{DC},3\phi}}{I_{\text{DC},3\phi}}No-load test

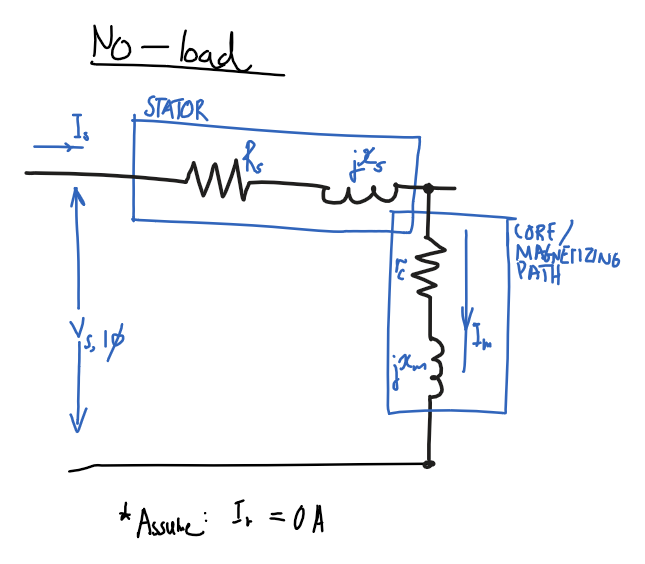

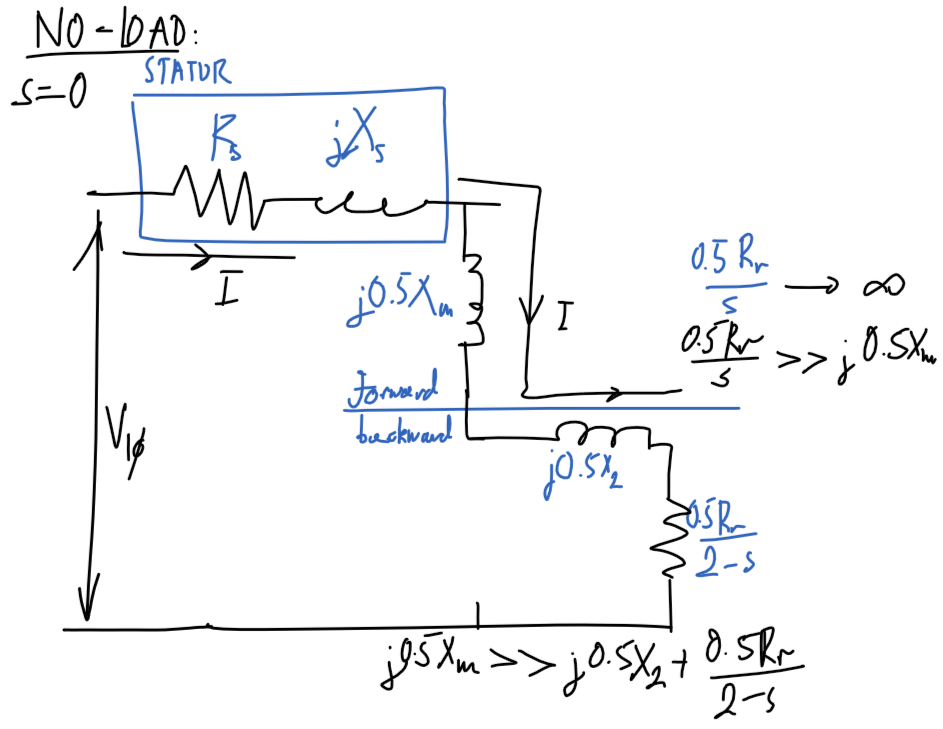

Assumptions

P_\text{out}=0- No output power as no load.

R_r/s=\inftyandI_r=0- Infinite rotor resistance, ignore rotor path.

Diagram

Using assumptions, remove rotor part of circuit and only consider stator and magnetizing path.

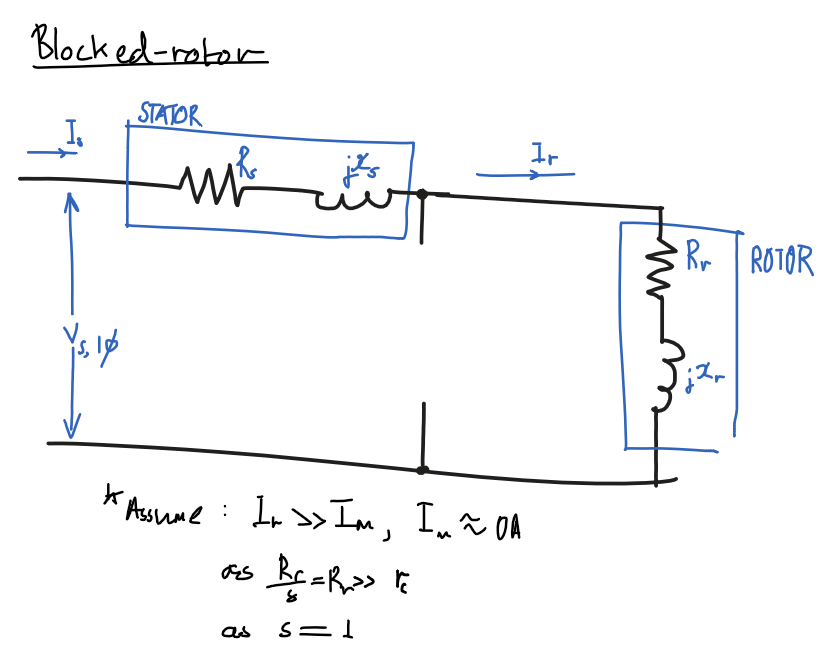

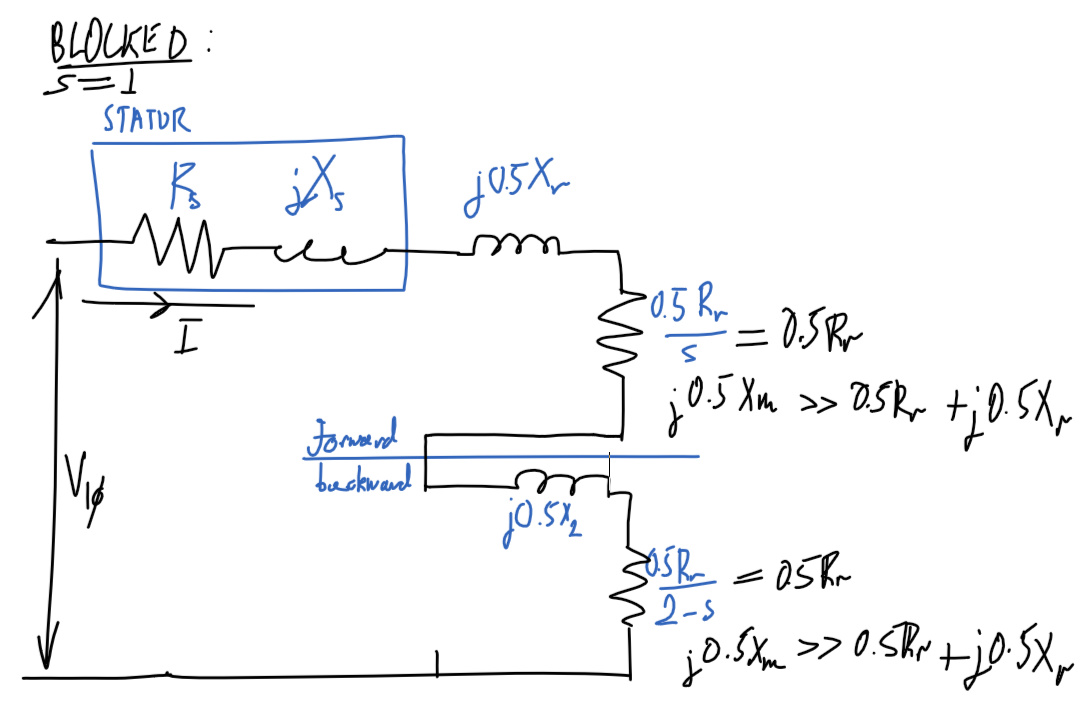

Blocked rotor test

Assumptions

- Ignore magnetizing path,

I_m=0I_r\ggg I_masR_r/s\ggg Z_m

R_r/s=R_r,s=1- Slip is

1as rotor is blocked.

- Slip is

x_s=x_r'- Same number of turns in stator and rotor

- and

x_r=f_0/f_\text{BL} \times x_r'- Note:

x_r'is the inductance atf_\text{BL}, the blocked rotor test frequency which is less than the nominal frequencyf_0

- Note:

Diagram

Ignore magnetizing path